The discharge of fats, oils, and greases to the sanitary sewer system is an important environmental and public health issue. Fats, oils, and greases(called FOG for short) build up in sewer lines over time, restricting the capacity of the pipes. Attempts to keep the sewer collection system flowing is a very costly and time consuming effort. Eventually, the pipes can become blocked completely, leading to overflows of raw sewage into streets, storm drains, and our creeks and rivers.

MGSD strives to keep all the sewer collection lines through enforcement of it’s Grease and Oil Control Program. The areas of concern or “hot spots” occur primarily in areas where restaurants are present. If not properly maintained, the grease interceptors can overflow and or cause blockages within the sewer collection lines.

Grease can also enter the environment from criminal grease management and disposal practices. MGSD aggressively pursues all violators. Businesses that are hiring grease haulers to clean and maintain their grease removal devices need to be careful about who they work with and monitor those activities closely.

The most effective way to reduce these problems is for residents and restaurants to do what they can to minimize the amount of these materials that they send to the sanitary sewer.

What we can do to help:

The easiest way to solve the grease problem and help prevent overflows of raw sewage is to keep this material out of the sewer system in the first place. There are several ways to do this:

Grease Removal Devices:

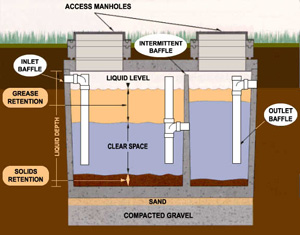

MGSD requires all food service facilities to install a grease interceptor with a minimum capacity of 750 gallons in accordance with it’s Grease and Oil Control Program. All food service facilities should be aware of the importance of installation and proper maintenance of grease removal devices. Existing ordinance provisions for food service facilities are designed to help minimize the impact that these businesses have on the sewage collection system within the boundaries of MGSD.

Grease interceptors are installed underground, outside of the food service facility. Grease traps, which are not allowed under the MGSD policies, are much smaller than grease interceptors, and are typically installed underneath or adjacent to a three-compartment sink.

Once a food service facility is using a grease removal device to prevent discharge of FOG to the sanitary sewer, it is very important that the device be properly maintained at an appropriate frequency. MGSD’s ordinance requires that the contents of grease removal devices be completely removed at intervals outlined within the ordinance. This means that each food service facility must hire a grease hauler to pump out its grease removal devices. Poorly maintained and undersized)grease removal devices can be the cause of backups, spills, and increased maintenance costs for the District.

Grease Haulers:

Grease haulers pump out the contents of grease removal devices and dispose of the grease at landfills that accept grease waste, or at sewage treatment facilities. Grease haulers pump out the contents of grease removal devices and dispose of the grease at landfills that accept grease waste, or at sewage treatment facilities. Unfortunately, many grease hauling companies have been caught illegally dumping grease from their clients’ grease removal devices into sewer manholes or storm drains. Grease can suffocate fish and is harmful to the plants and animals that inhabit the creeks, streams, lakes, and rivers. Food service facilities can be held responsible when grease from their facilities is improperly handled, and can face large fines as a result. To protect your business and the environment you should closely monitor the activities of the grease hauling companies they hire to be certain that they are acting responsibly. It is recommended that an employee be assigned to supervise the grease hauler. Ask questions about how the hauler handles the grease waste from your facility. Very low prices for grease pumping and hauling services may be an indication that the hauler is not properly disposing of the grease. It is also important that grease removal devices be cleaned in accordance with MGSD policies. In some instances, the grease removal device needs to be cleaned out far more frequently to prevent FOG from passing through the device and into the sewer.